Key Takeaways

- Skipping Maintenance Increases Risk of Downtime: Hidden faults like battery degradation, worn components, and outdated firmware often go unnoticed until a failure occurs. Regular maintenance is essential to uncover and address these vulnerabilities early.

- A Structured Maintenance Programme Supports Business Continuity: Proper load testing, firmware updates, environmental checks, and predictive reporting are the backbone of a reliable UPS system. These elements work together to enhance system performance and support long-term downtime prevention.

- Proactive Servicing Saves More Than Just Cost: Beyond reducing the risk of system failure, a consistent maintenance routine extends the lifespan of your UPS, improves safety, and helps with smarter budgeting through data-driven planning and reporting.

Introduction

In our increasingly digital world, organisations rely on a stable, uninterrupted power supply to keep operations running seamlessly. Whether it’s a server room handling e-commerce transactions, a hospital’s life-saving equipment, or a financial institution processing thousands of operations per second, any interruption can lead to significant operational and financial damage.

While investing in a quality Uninterruptible Power Supply (UPS) system is a good start, many companies mistakenly treat it as a one-time solution. The truth is, a UPS is only as reliable as the maintenance behind it. Without regular servicing, critical components can silently degrade over time, leaving your business vulnerable to failure at the worst possible moment.

This is where downtime prevention becomes mission-critical. Rather than waiting for problems to surface, businesses must take a proactive approach by implementing a structured UPS maintenance strategy. In high-stakes environments, it’s not just about keeping the lights on—it’s about protecting your people, your data, and your reputation.

In the upcoming sections, we’ll explore the key components of effective UPS maintenance and how it plays a critical role in downtime prevention. This guide is designed to give you both the strategic and practical knowledge needed to maintain business continuity with confidence. No matter if you’re overseeing IT infrastructure, managing facilities, or responsible for business continuity, this guide will help you put in place a solid downtime prevention strategy.

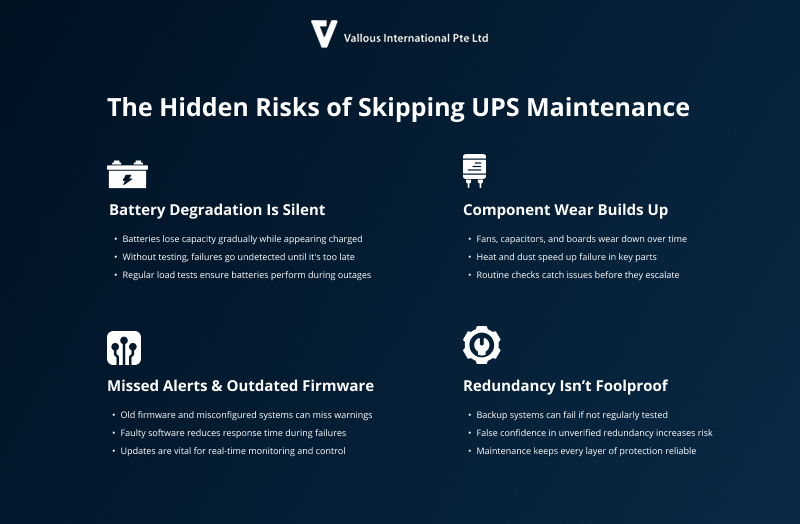

The Hidden Risks of Skipping Maintenance

Before you assume your uninterruptible power system is in the clear, consider this: most failures don’t happen overnight—they build up quietly over time. When regular servicing is skipped, the hidden risks compound, and by the time an issue surfaces, it’s often too late. True downtime prevention means staying ahead of these problems before they interrupt your operations.

1. Battery Degradation Isn’t Always Obvious

UPS batteries don’t usually fail all at once. They degrade gradually, losing capacity even while appearing fully charged. Without load testing or impedance analysis, this decline goes unnoticed until the moment power is lost, and the batteries can’t deliver. This silent failure can be catastrophic, especially in high-dependency environments like data centres or hospitals. Regular testing is a critical part of downtime prevention, ensuring your batteries will perform when needed most.

2. Component Wear Compounds Over Time

Internal components such as fans, capacitors, and circuit boards are subject to wear and tear, particularly in warm, dusty, or high-load environments. Over time, this stress causes parts to overheat, malfunction, or fail completely. If not identified and addressed during routine inspections, these small issues can snowball into major disruptions.

3. Missed Alerts and Firmware Issues

UPS systems rely on software to monitor health, trigger alerts, and control responses. If firmware is outdated or monitoring systems are misconfigured, early warnings can be missed entirely. These invisible failures can compromise your system’s ability to respond to an outage, reducing your margin for recovery. Firmware updates are not optional—they’re essential for modern downtime prevention.

4. False Sense of Security in Redundant Systems

Redundancy provides peace of mind, until it doesn’t. Backup systems that haven’t been tested or maintained can fail just as easily as your primary UPS. Without verification, redundancy can create a dangerous illusion of safety. Maintenance ensures that every layer of your protection is functional and reliable when the unexpected strikes.

In summary, skipping UPS maintenance introduces risks that are entirely avoidable. Small problems go unnoticed, software becomes outdated, and critical systems may fail silently. By making regular servicing a priority, you strengthen your strategy for proactive downtime prevention, protecting your operations, your data, and your bottom line.

Anatomy of a Good Maintenance Programme

Now that we’ve explored the risks of skipping maintenance, the next step is understanding what a robust maintenance programme actually looks like. A comprehensive maintenance plan goes beyond visual checks. It combines technical testing, software updates, environmental reviews, and actionable reporting to keep your power infrastructure dependable and future-ready.

Below, we break down the key components that make a UPS maintenance programme truly effective.

1. Comprehensive Electrical and Battery Testing

At the core of any good maintenance programme is thorough battery testing. Load tests, impedance checks, and runtime simulations aren’t just routine—they’re essential. These tests provide a real-time picture of your UPS system’s performance, flagging hidden issues in power delivery or battery capacity before they become critical. This proactive insight is key to ensuring downtime prevention is rooted in real data, not assumptions.

2. Firmware Updates and Calibration Checks

Technology moves quickly, and so do the threats. If your UPS power backup firmware isn’t regularly updated, you could miss vital improvements that enhance fault detection and efficiency. Calibration checks also ensure that alerts and system responses are accurate, keeping your protection sharp. These updates not only optimise performance but also strengthen your downtime prevention efforts by eliminating blind spots.

3. Environmental and Physical Inspection

It’s not just what’s inside the UPS that matters. External conditions like dust, moisture, poor ventilation, or high heat can quietly shorten component life. A detailed inspection will catch early signs of corrosion, damaged wiring, or blocked airflow, issues that are easy to overlook but costly when ignored.

4. Service Reporting and Predictive Recommendations

Maintenance doesn’t end when the technician packs up. A quality programme includes comprehensive reporting, giving you a clear view of current system health, potential risks, and recommendations for upgrades or replacements. These insights support budgeting and planning while keeping downtime prevention at the centre of your operational strategy.

In short, a well-structured maintenance routine transforms your UPS system from a passive backup into a reliable, actively managed shield against disruption. Going beyond just about fixing problems, a good maintenance programme is also about staying several steps ahead.

Choosing Between Half-Yearly and Yearly Plans

After covering what a solid UPS maintenance programme should include, it’s time to consider how often these checks should happen. Choosing between half-yearly and yearly maintenance plans from an uninterruptible power supply supplier depends on several key factors, none of which should be overlooked if downtime prevention is a priority.

1. System Age and Usage Intensity Matter

If your system is relatively new and not operating under strenuous conditions, an annual check-up may suffice. But for older systems or those that run 24/7 under heavy loads, such as in logistics centres, manufacturing facilities, or server rooms, minor issues can quickly escalate over long gaps. In these high-stress environments, downtime prevention demands a more frequent approach, making half-yearly servicing the smarter choice.

2. Environmental Factors Can Accelerate Wear

No UPS system operates in a vacuum. Humidity, poor airflow, heat fluctuations, and even dust accumulation can take a toll on internal components. In such environments, yearly maintenance may not be enough. Semi-annual inspections give technicians the chance to catch early signs of corrosion, filter blockages, or electrical inefficiencies—all of which can undermine performance and sabotage downtime prevention efforts.

3. Downtime Tolerance and Business Risk Profile

Different industries carry different levels of risk when it comes to unplanned outages. If your business is in healthcare, data hosting, finance, or critical infrastructure, your tolerance for disruption is close to zero. In these cases, erring on the side of caution with biannual maintenance is not just wise, it’s essential.

4. Bundling Maintenance with Emergency Support

At Vallous International, we also offer bundled UPS maintenance service plans that include 24/7 onsite emergency support. This means you’re never left exposed between scheduled visits, allowing for true peace of mind. When maintenance and rapid-response services are integrated, your organisation benefits from a more holistic, responsive strategy.

Ultimately, whether you choose a half-yearly or yearly plan, the decision should align with your operational demands and risk tolerance, not just your calendar.

What Happens During a Vallous International UPS Service Visit

Once you’ve selected the right maintenance schedule, be it yearly or half-yearly, the next question is: what actually happens during a UPS service visit? At Vallous International, each visit is designed with downtime prevention as the core objective. This isn’t just a basic check-up—it’s a structured process focused on ensuring long-term system health and uninterrupted power reliability. Here’s what we actually do.

1. Thorough Internal and External Inspection

Our service engineers begin with a detailed physical inspection of your UPS unit. This includes checking for loose wiring, rust or corrosion on terminals, dust accumulation in cooling fans, and any physical signs of wear. These early indicators can point to bigger problems down the line, and catching them early is one of the cornerstones of downtime prevention.

2. Battery and Load Testing

Batteries are the lifeblood of any UPS system. We conduct real-time simulations to assess how your UPS responds under different load scenarios. From checking hold time to observing how the system handles abrupt surges, these tests provide a snapshot of battery performance. Weak batteries are one of the leading causes of unexpected outages, so this step plays a direct role in downtime prevention.

3. System Diagnostics and Software Tuning

Beyond the hardware, our engineers run a complete software and diagnostics check. We update firmware, calibrate alarm thresholds, review event logs, and adjust internal configurations to optimise performance. This tuning ensures your UPS reacts swiftly and accurately during an actual power disruption, enhancing your downtime prevention strategy at a software level.

4. Clear Post-Service Reporting and Guidance

Every Vallous visit concludes with a comprehensive service report. This includes the current health of your system, any potential risks, and personalised recommendations for next steps. Whether it’s a minor part replacement or a strategic system upgrade, our advice is tailored to support your long-term operational goals and maintain your downtime prevention framework.

A Vallous UPS service visit is a proactive, precision-driven session aimed at keeping your business powered, protected, and prepared.

Frequently Asked Questions

1. How long does a typical Vallous UPS service visit take?

A standard UPS service visit by Vallous International typically takes between 2 to 4 hours, depending on the system size and complexity. For larger or mission-critical installations, the service duration may extend slightly to ensure thorough testing and diagnostics. Our goal is to complete all assessments efficiently without disrupting your operations, supporting both reliability and effective downtime prevention.

2. Can UPS maintenance be performed without disrupting business operations?

Yes. Most routine UPS maintenance can be conducted with minimal or no downtime, especially in systems with built-in redundancy. Vallous engineers plan service visits carefully to avoid disrupting critical operations and will advise if a temporary power transfer is necessary.

3. What are the warning signs that my UPS needs urgent attention?

Common red flags include unusual noises, frequent alarms, unexpected shutdowns, reduced battery runtime, or visible wear on components. If any of these occur, it’s best to schedule a service inspection immediately—even if you’re not due for a routine check.

Conclusion

When it comes to critical infrastructure, downtime prevention isn’t a luxury—it’s a necessity. Skipping routine maintenance or delaying system upgrades may save money in the short term, but the cost of unexpected power failures can be far greater. A well-structured UPS maintenance plan not only ensures consistent performance but also extends the lifespan of your equipment, giving your business the operational resilience it needs.

Whether you’re weighing the frequency of servicing, evaluating risks, or simply want clarity on what a proper UPS check-up looks like, planning with the right partner makes all the difference.

At Vallous International, we don’t just maintain systems—we help businesses safeguard uptime, data, and reputation. Our UPS maintenance solutions are tailored for your load, environment, and risk tolerance, with expert engineers and 24/7 support bundled into every plan.

Reach out to us today to discuss a maintenance schedule that fits your operations, and let’s build a power strategy designed for long-term performance and protection.